In the fast-paced world of appliance and consumer products manufacturing, C parts for the appliance industry are often overlooked, yet they play a crucial role in ensuring the success of both the product and the entire production process. These tiny components, though seemingly insignificant, are vital to the overall functionality and quality of appliances. Let’s explore how C parts are critical to this industry and why managing their supply chain efficiently is key to staying competitive.

What Makes C Parts So Crucial in the Appliance Industry?

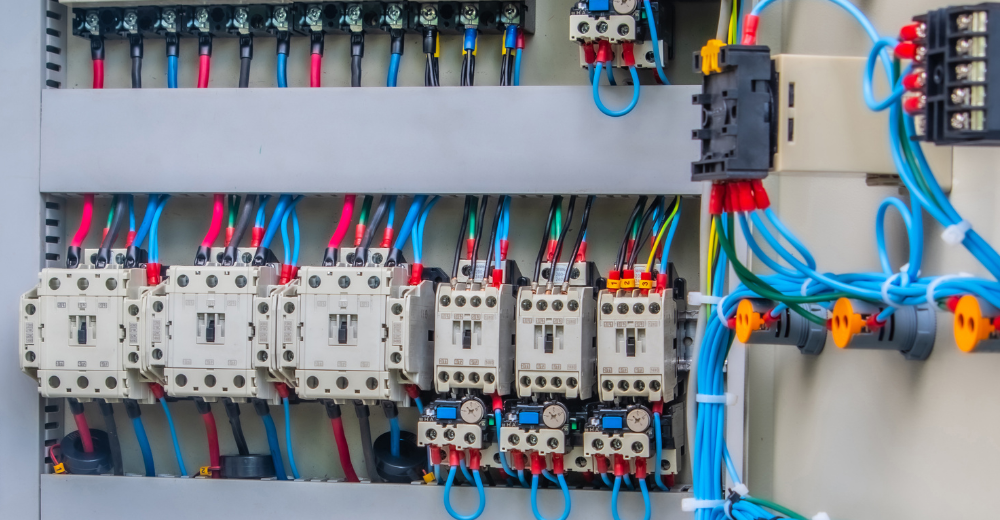

C parts for the appliance industry are small, low-cost components such as screws, washers, springs, and fasteners that manufacturers use in bulk. Their value may seem minor when looked at individually, but their absence can cause significant production bottlenecks and product failures. For example, a missing screw might seem trivial, but it can stop a washing machine from being fully assembled or cause a dishwasher to malfunction.

These parts, although often underappreciated, form the skeleton of most appliances and consumer goods. Without them, larger components can’t be held in place, and the overall product may fail to meet safety or performance standards. For manufacturers, ensuring the right quality and quantity of C parts for the appliance industry at the right time is critical for the entire production line.

How C Parts Influence Efficiency and Quality

While C parts for the appliance industry are tiny, their role in maintaining product quality and operational efficiency is enormous. These components directly impact:

- Product Reliability: Poor-quality or missing C parts can lead to malfunctions, compromising product reliability and potentially causing safety hazards. A single defective fastener could be the difference between a well-functioning appliance and a costly product recall.

- Production Continuity: The lack of a steady supply of C parts can grind the production process to a halt. If even one component is delayed, the entire assembly line may stop, delaying shipments and frustrating customers.

- Cost Management: The high volume of C parts used in production means that even slight inefficiencies in their supply chain can lead to significant cost overruns. Overordering creates excessive stock, tying up capital, while underordering can create supply shortages and expensive rush orders.

Overcoming Supply Chain Challenges for C Parts

Managing C parts for the appliance industry efficiently is no small task. Their large quantities and small size make inventory management challenging, and disruptions in their supply chain can have far-reaching consequences. When shortages happen, manufacturers face:

- Production Delays: Even a minor delay in C parts delivery can stop an entire production line, delaying product launches or pushing back orders.

- Increased Costs: Last-minute sourcing of C parts often results in premium prices, expedited shipping costs, and operational disruptions.

- Quality Risks: In an attempt to meet tight deadlines, companies may cut corners by sourcing from unreliable suppliers, increasing the risk of defects.

Given these risks, manufacturers must have a well-organized and reliable system in place to avoid disruptions.

Building a Resilient Supply Chain for C Parts

Ensuring the availability and quality of C parts for the appliance industry requires a thoughtful approach. Here’s how manufacturers can build a more resilient supply chain:

- Invest in Supplier Relationships: Rather than simply treating suppliers as transactional partners, manufacturers can benefit from building long-term, strategic relationships. Open communication and trust allow suppliers to better understand your needs, respond to demand fluctuations, and maintain a consistent supply of C parts.

- Global Sourcing for Risk Mitigation: A global supply base diversifies sourcing, reducing dependence on any single region or supplier. When geopolitical events, natural disasters, or logistics disruptions occur in one region, manufacturers with diversified sourcing strategies can minimize the impact on production.

- Advanced Inventory Management Systems: Utilizing advanced software and vendor-managed inventory (VMI) systems enables manufacturers to maintain optimal stock levels without overordering. VMI systems automatically track inventory, trigger reorders, and ensure timely delivery to prevent shortages while reducing excess.

- Quality Assurance Programs: Consistency is key when dealing with high-volume, low-cost parts. Manufacturers should implement strict quality checks and collaborate closely with suppliers to maintain high standards across all deliveries. Poor-quality C parts can lead to expensive failures later in the production process.

Gexpro Services: Simplifying the Supply Chain for C Parts

At Gexpro Services, we recognize the hidden importance of C parts for the appliance industry and how their availability can make or break a production process. We focus on streamlining the supply chain for manufacturers, ensuring that C parts are readily available, high-quality, and cost-effective.

What We Offer:

- Global Sourcing Network: With connections to manufacturers and suppliers worldwide, we can ensure a diversified and reliable supply of C parts, helping you avoid disruptions.

- Customized Inventory Solutions: Through our vendor-managed inventory system, we take the burden off your team, ensuring that stock levels are optimized and automatically replenished as needed.

- Tailored Solutions for Unique Needs: No two manufacturing operations are the same. We work closely with our clients to create custom solutions that fit their specific production schedules, quality requirements, and budgetary constraints.

- Strict Quality Control: We know how vital quality is in the manufacturing of consumer products. That’s why we rigorously vet our suppliers and enforce strict quality assurance processes to deliver parts that meet your exact specifications.

Conclusion: The Importance of C Parts in the Appliance Industry

In the appliance and consumer products industry, the smallest parts often carry the largest weight in determining success. Efficiently managing the supply of C parts for the appliance industry can boost productivity, lower costs, and ensure that the final product meets the highest standards of quality and reliability.

Gexpro Services is here to ensure your supply chain remains strong, efficient, and cost-effective, freeing you to focus on what matters most—delivering exceptional products to your customers. Contact us today to learn how we can help you optimize your C parts supply chain, streamline your operations, and enhance the quality of your products.