Companies are constantly seeking ways to reduce costs and improve efficiencies without compromising on quality. Value engineering is a strategic approach that focuses on maximizing functionality while minimizing costs by standardizing the bill of materials (BOM), identifying product cost-saving opportunities, and improving engineering processes. Did you know that 80% of the cost of the components in assemblies comes from associated costs, not direct material costs? Learn how your facility can achieve significant cost reductions and streamline your operations by using value engineering.

Standardizing the Bill of Materials (BOM)

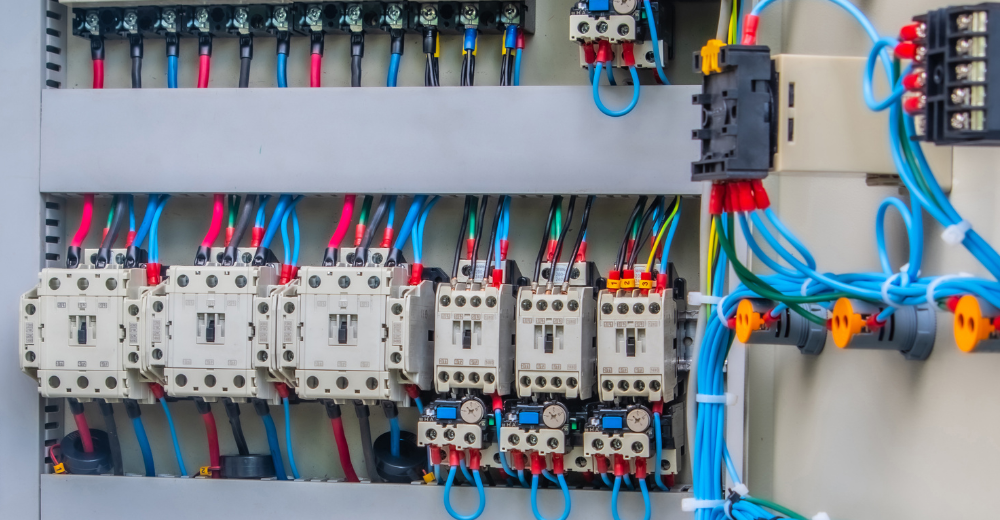

A Bill of Materials (BOM) is a comprehensive list of parts, components, and assemblies required to build a product. Standardizing BOM involves creating a uniform structure and format for listing these items, ensuring consistency across different products and projects. This will:

- Improve consistency across departments

- Simplify the inventory process

- Provide opportunities for bulk purchasing, which reduces costs

Identifying Product Cost-Saving Opportunities

Product cost savings can be identified by a careful review of design, materials, and manufacturing processes. Strategies include:

- Replacing more expensive materials with lower-cost alternatives

- Negotiating with suppliers to secure better pricing

- Evaluating each component to determine if there are more effective ways to achieve the same results

These actions can lead to significant cost savings for your organization.

Engineering Process Improvements

Improving engineering processes is a crucial component of value engineering. Strategies include:

- Eliminating waste

- Improving workflows

- Investing in technologies that can automate processes to reduce manual labor

- Encouraging collaboration and employee feedback to suggest process enhancements

Your organization can gain significant efficiencies by looking for improvements within the engineering process.

Staying competitive within your market can be challenging, but with a strategy in place to standardize BOM, identify cost-saving opportunities, and improve engineering processes, you can reduce costs and simplify operations. Gexpro Services helps Original Equipment Manufacturers (OEMs) remain competitive in the marketplace by reducing costs through value engineering practices and solutions.

For more details on how value engineering can transform your business operations, or to schedule a consultation, please reach out to Gexpro Services. Together, we can drive cost efficiency and simplification in your manufacturing processes.